HISTORY

1970

Company foundation

Gerhard Kuppler and Wolfgang Herrmann founded Kuppler + Herrmann GmbH. At first a shed served as a production hall.

At that time Mr. Kuppler was already an independent businessman with 2 trucks in posession and Mr. Herrmann was a lathe operator. They bought a carousel lathe on which they manufactured precision turned parts, up to 2.000 mm in diameter, for the area of knitting machine manufacturing.

1986

Construction of the current location and introduction of a new carousel lathe

The “shed” became too small and the construction of today’s company began. Hall 1 and the office building in front of it were built.

A conventional carousel lathe with a turning diameter of up to 3.500mm was also introduced.

1988

The introduction of CNC technology

The first CNC carousel lathe was bought. With this we could manufacture turned parts with a diameter of up to 3.500 mm. This enabled us to significantly expand our range of services.

1991

The 1st drilling machine was introduced

By using the universal drilling and milling machine San Rocco – Futura 140 with a patented special spindle head, we were immediately able to offer the highest precision in the area of drilling and milling. This enabled us to further optimize our range of products and services.

1997

Expansion of the machine park with a CNC-controlled machining center

By using a DÖRRIES Scharmann SOLON 4 with a pallet changer, as well as a BURKHARDT + WEBER – MC 80 and finally a HELLER – BEA2, we were able to produce serial parts in a fast manner and cost efficient.

1998 und 1999

Huge change in management at Kuppler + Herrmann GmbH

1998 – Mr. Herrmann retired.

1999 – Kuppler + Herrmann GmbH became to be Kuppler GmbH managed by Gerhard and Heiko Kuppler.

2001

Expansion of the production by Hall 2 and the addition of the office building

With these additions we increased the production area to 2.400 square meters. At the same time we increased the crane capacity to 40t. And we started up a TOS drilling machine with a rotary table. This drilling machine has the process paths X = 5.000 mm and Y = 3.000 mm.

2002

New purchase of our largest carousel lathe

Now we can machine turned parts up to a diameter of 4.000mm.

2003

Expansion of the production by Hall 3

With this step we enlarged our production space by 400 sqm.

2008

Construction of hall 4 and expansion of the machine park

With the new hall, another 700 sqm of production space has been gained.

We filled this area with 4 more new machines.

In the turning area, the production facilities were increased in size with a diameter of up to 3.400 mm and a maximum height of 2.800mm.

New machines were purchased for the drilling machine area, with which we can now drill and mill parts in X = 4.000 mm and Y = 3.000 mm.

2012

New construction of hall 5

We have built Hall 5 so that we can now store our customers‘ parts in the dry.

2013 und 2014

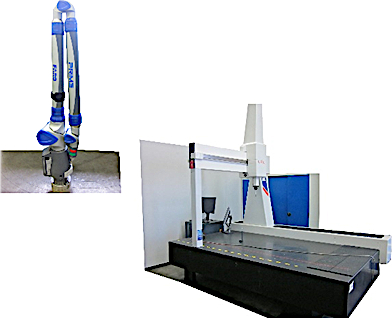

New measurement technology for better quality assurance

Since 2013 it has been possible for us to check the dimensions of components directly on the machine. We have acquired a FARO measuring arm to measure and document them against a data record. Technical data: FARO Prime 2,4 m, 6 axes, with the support of the CAM2 Measure 10 software.

In 2014, the tactile CNC 3D coordinate measuring machine from LK (G-90C) was introduced. It is now possible for us to test and document components with dimensions of 2.000 mm x 1.200 mm x 1.000 mm in air-conditioned surroundings.

2016

Expansion of our machine park with two new machines

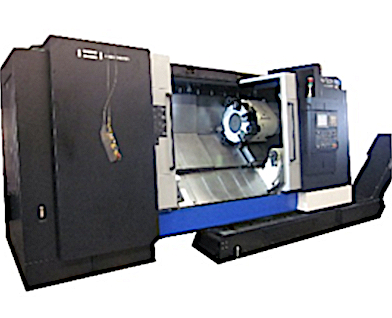

In order to meet the demands of our customers, we bought a new lathe. The first horizontal lathe at Kuppler GmbH.

A HWACHEON – Hi-TECH 700 with Fanuc 0i-TD control. With this we can now turn small parts from 100 mm to 680 mm in diameter.

The 5-axis machining center from BURKHARDT + WEBER – MC 120 HV with SIEMENS-SINUMERIK 840D control was also added. This has the following procedures:

X = 2.800 mm, Y = 1.800 mm, Z = 1.800 mm, B = rotary indexing table 360.000 x 0,001 ° and an H + V head.

2020

we celebrate the 50th company anniversary of Kuppler GmbH!